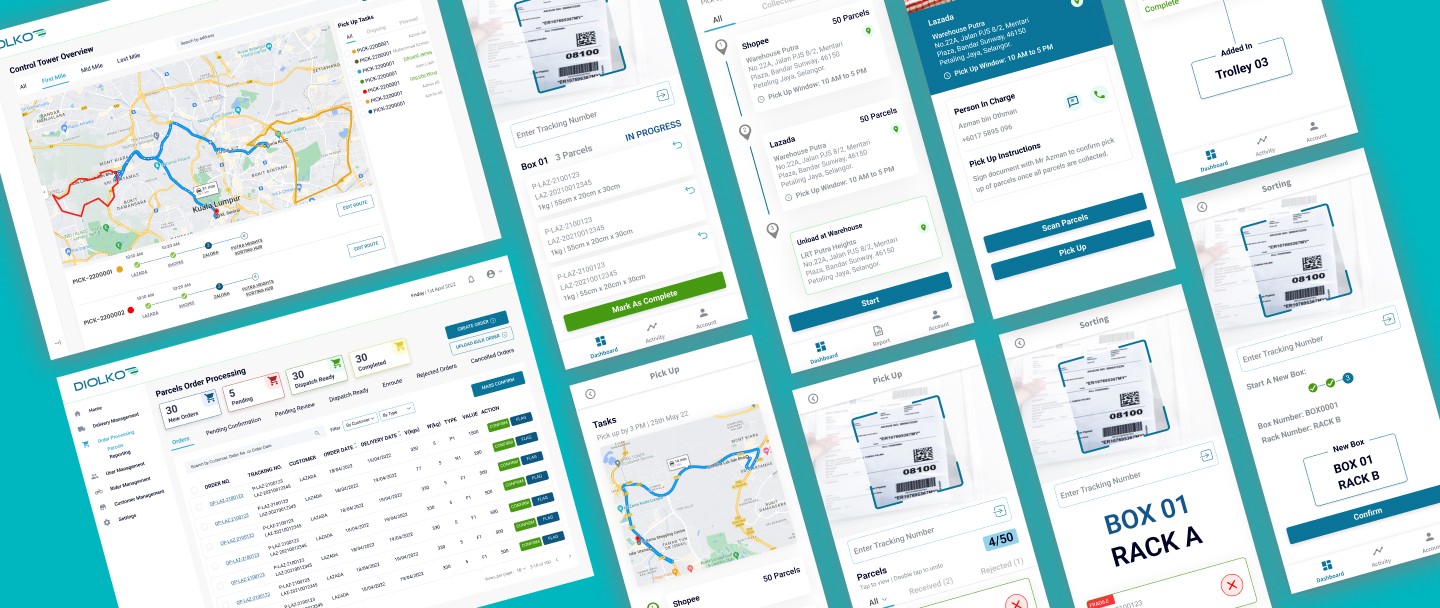

The Challenge

There were a few challenges in this project. Firstly, it was the company’s chosen method of sorting parcels to use containers to group parcels going to same locations together, this meant that the staff performing the sorting task had to be informed via their mobile apps, which containers to put the parcels in.

Another challenge was to increase staff efficiency by reducing the number of taps on the mobile app and making it almost automatic while still giving them options to make changes as needed.

The Chosen Devices

Requirement Gathering

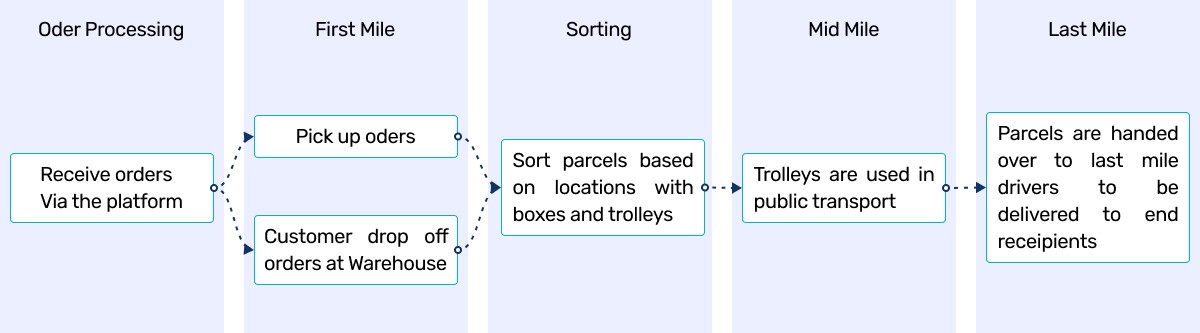

Requirement gathering for this project took a long time as I had to understand the logistics industry prior to grasping the requirements provided by the company. However, the founders of the company already had a background in logistics and a lot of experience to tap into.

Here, we spent a lot of time understanding and kept visiting this step of the design pathway every now and then to confirm and rethink operating processes.

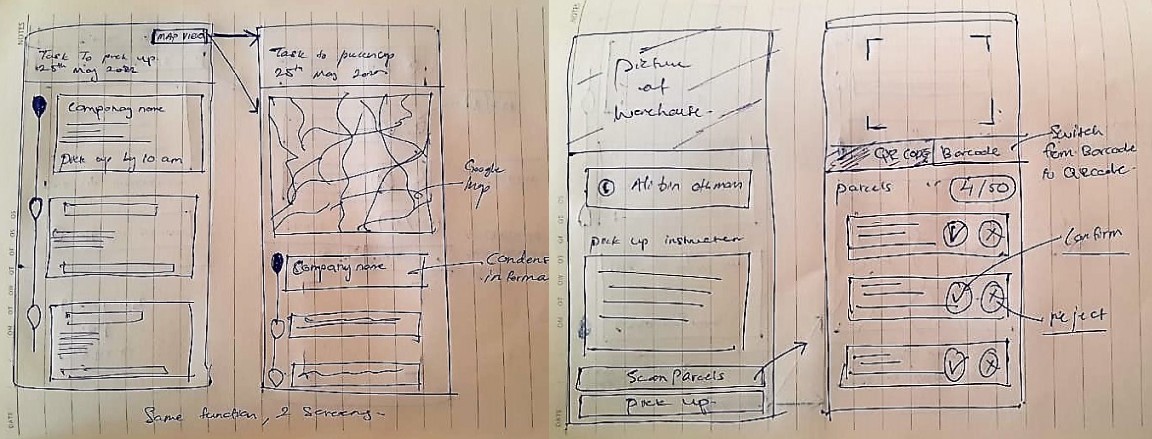

Analyse and Plan

Once I had gotten all the requirements and have had a good understanding of the standard practices of the industry, I started sketching my designs.

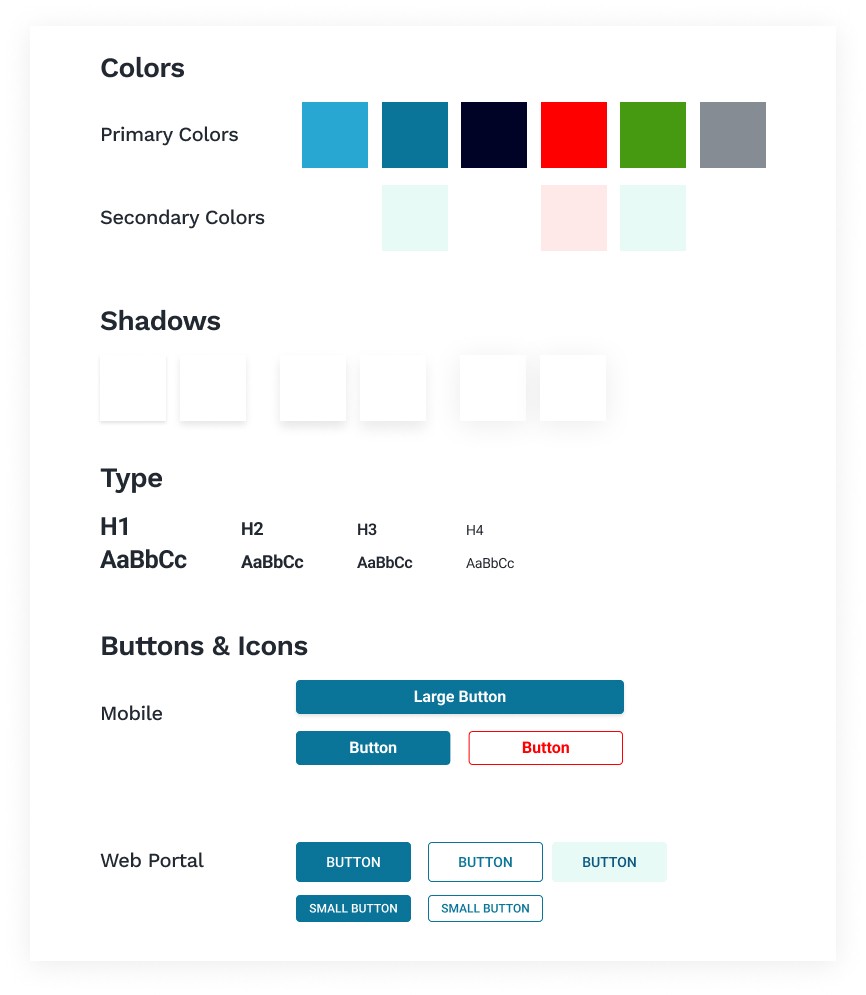

Creating a Design System

Before starting any project, I was taught early on by a fellow UIUX design mentor to always create design systems. These systems do not only standardise the design across the product, but has also proven to save a lot of time by creating components. Making minor changes to components created is very easily done with a design system in place.

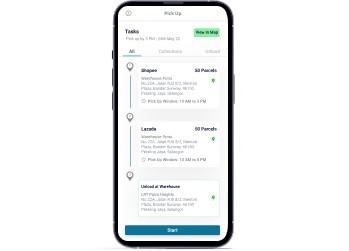

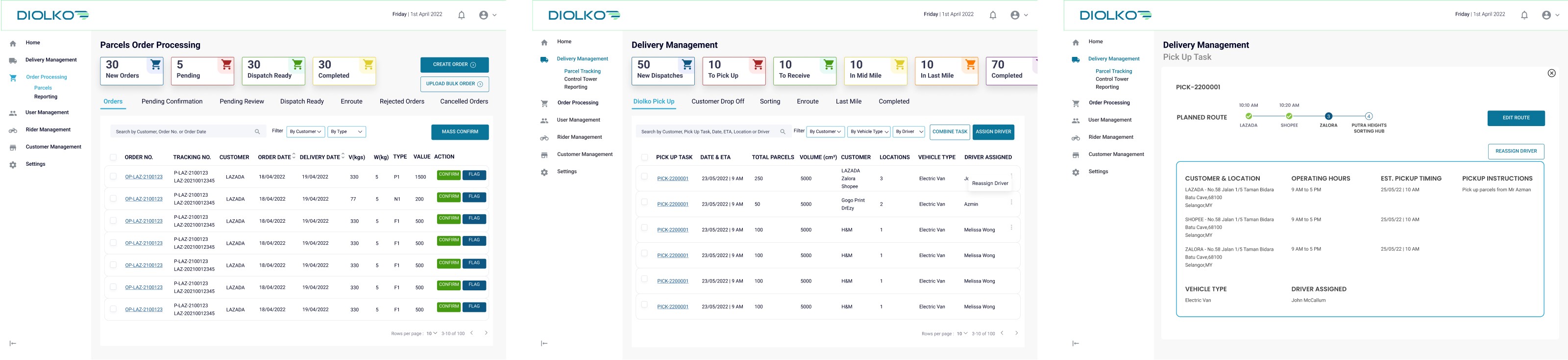

The Solution

Sorting

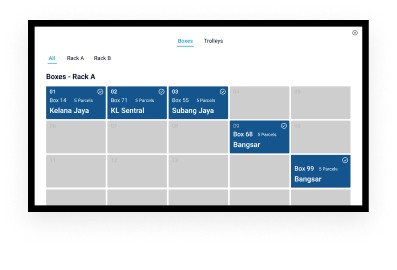

After pick up or drop offs by the customer, all parcels are sorted according to their destinations.

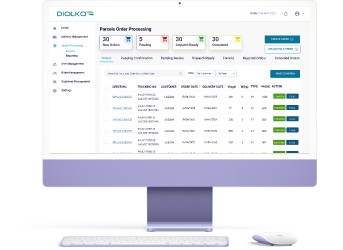

The routing algorithm sorts all parcels into batches and the information is displayed in the web portal for staff to check and make changes if necessary in the case of train line closures or breakdowns.

As for the staff performing sorting, information will be displayed to them when they scan the parcel. The information displayed will inform the team to place it in a particular box, start a new box or place it directly in a trolley. For staff that is just moving trolleys from the sorting hub to the platform, the TV screens will display the trolleys that are ready and those upcoming.

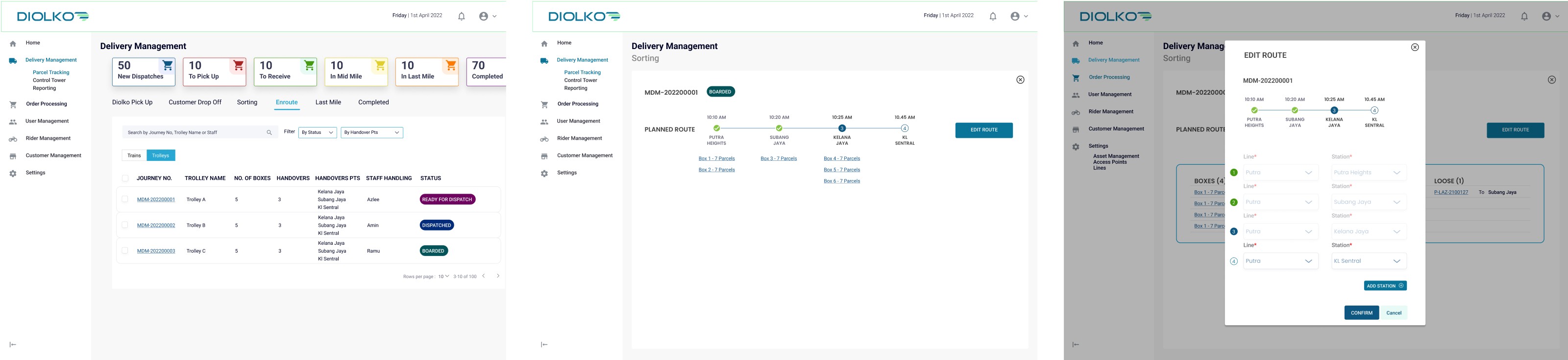

Mid Mile

After parcels are sorted in their respective boxes and trolleys, they are loaded onto the trains for the mid-mile journey. Here, the web portal displays the route and allows the staff to edit the route if necessary while the operations staff on the train platform uses the mobile app to load or unload trolleys from the train. While on the train, the team is informed of the trolleys to unload and receive at the next station.

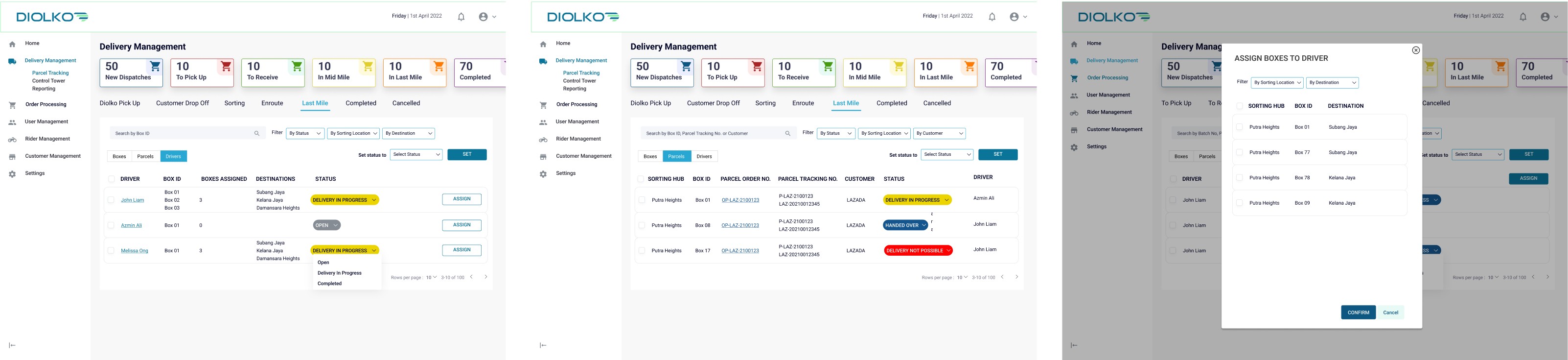

Last Mile

Once they are unloaded from the train, the trolleys are broken down into boxes for the last-mile delivery riders/drivers to deliver them. The staff at the last-mile station will be able to break the trolleys and hand the boxes over to the last-mile delivery driver via the mobile app.

Once, the delivery rider/drivers receive their boxes, they will be updated with a new delivery list. Upon delivery, riders/drivers must take a picture to prove delivery.